Extreme-Climate Energy Storage

Our Mission

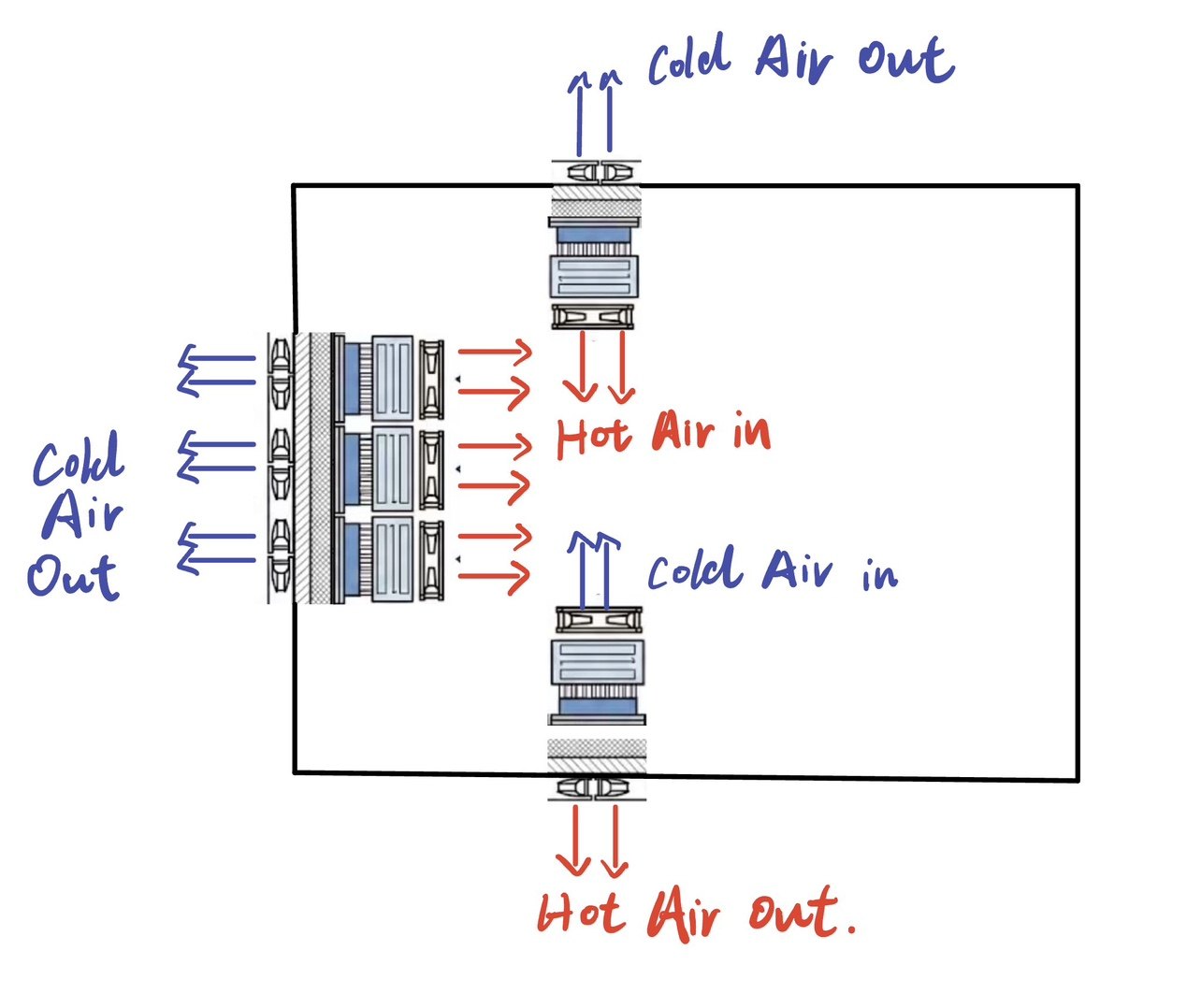

Aegis exists to make battery energy storage dependable in places where weather is the biggest variable. We create a stable enclosure environment so projects can run consistently through heat, cold, wind, and rapid day–night swings.

By keeping batteries in a healthier operating window, Aegis helps reduce unplanned downtime, slow degradation, and improve real-world system reliability—so extreme sites become practical, long-term deployments.

Our Innovation

Aegis isn’t just insulation and airflow. The core is a predictive ADRC control layer that estimates disturbances in real time—sun load, wind chill, ambient swings, lid opening, and internal heat changes—and corrects before the enclosure drifts out of range.

That control stack (observer design, tuning, and condensation-aware constraints) is the hard part to replicate. It turns extreme sites into repeatable operating conditions, which translates directly into less downtime and longer battery life.

Our Values

-

Outcome-Driven

We focus on what operators pay for: stable performance, fewer incidents, and less downtime.

-

Built on Control, Not Hype

ADRC-based prediction and disturbance rejection is our edge, and we validate it with data.

-

Designed for Real Sites

Day–night swings, wind, dust, and sudden weather changes are treated as defaults, not exceptions.

-

Economic by Design

Reliability improvements translate into lower OPEX and longer asset life over the project cycle.